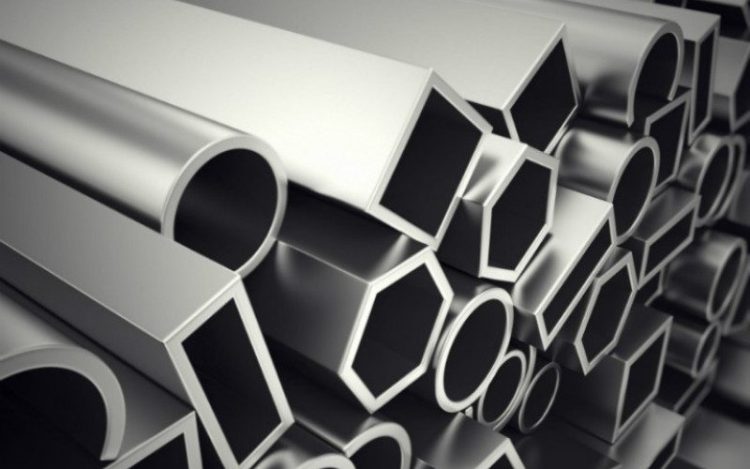

In today’s fast-paced manufacturing landscape, efficiency, cost savings, and adaptability are crucial for staying ahead. One innovation that has quietly revolutionized production across sectors is the use of Extruded Aluminum Shapes . This search phrase is becoming increasingly popular among professionals seeking to optimize design flexibility and production speed. By leveraging these advanced materials, American industries are discovering new ways to enhance quality while reducing lead times and expenses.

The Advantages of Aluminum Extrusions in Manufacturing

Aluminum’s unique properties—lightweight, corrosion-resistant, and highly malleable—make it an ideal material for numerous applications. When this metal is extruded into custom shapes, it offers a range of benefits that traditional fabrication methods simply cannot match.

Design Flexibility and Customization

Extrusion allows manufacturers to create complex profiles with precise tolerances. This flexibility enables:

• Tailored solutions: Engineers can design parts that fit exact specifications, eliminating the need for secondary machining.

• Integrated features: Channels, grooves, and attachment points can be built directly into the profile, reducing assembly steps.

• Rapid prototyping: New designs can be tested and adjusted quickly, which is vital for industries where innovation drives competitiveness.

Enhanced Efficiency and Cost Savings

The streamlined nature of extruded aluminum shapes translates directly into operational efficiencies:

• Reduced material waste: The extrusion process maximizes raw material usage, minimizing scrap.

• Lower labor costs: Fewer manufacturing steps mean less manual intervention, which cuts down on labor hours.

• Shorter production cycles: With parts that arrive ready to assemble, manufacturers can move products to market faster.

Superior Performance and Sustainability

Aluminum extrusions are not just about efficiency—they also deliver performance and environmental benefits:

• Strength-to-weight ratio: These shapes are strong yet light, making them perfect for applications requiring durability without heaviness.

• Corrosion resistance: Aluminum naturally forms a protective oxide layer, making it ideal for demanding environments.

• Recyclability: Aluminum can be recycled repeatedly with minimal loss of quality, supporting sustainable manufacturing practices.

Applications Across American Industries

The versatility of extruded aluminum shapes makes them indispensable in a wide range of sectors:

1. Automotive: Used in chassis components, roof rails, and structural supports to reduce vehicle weight and improve fuel efficiency.

2. Construction: Frames, window supports, and curtain wall systems benefit from the strength and design flexibility of aluminum extrusions.

3. Electronics: Heat sinks and enclosures are easily manufactured to precise specifications, ensuring optimal performance.

4. Aerospace: Lightweight, high-strength parts contribute to fuel savings and increased payload capacity.

5. Renewable Energy: Solar panel frames and wind turbine components utilize extruded profiles for their durability and ease of assembly.

Streamlining the Future of Manufacturing

As the manufacturing sector evolves, the demand for materials that enable faster, smarter, and more sustainable production will only grow. Extruded aluminum shapes provide American industries with the tools needed to meet these challenges head-on. By embracing this technology, companies can achieve greater design freedom, improve operational efficiency, and support environmental goals. The result is a manufacturing process that is not only more streamlined but also better equipped to adapt to the demands of tomorrow’s marketplace.