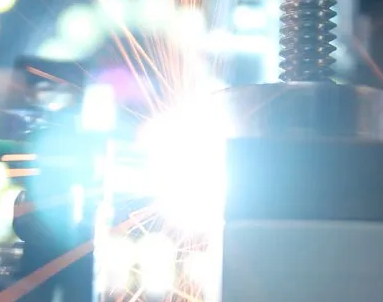

Achieving superior strength and durability in metal fabrication requires more than just the right materials; it demands the most advanced joining methods. For professionals and hobbyists striving to enhance the quality of their metalwork, Precision Tig Welding stands out as one of the top search solutions for delivering clean, high-integrity welds on a range of metals, from stainless steel to aluminum alloys.

What Sets Precision Tig Welding Apart?

Tungsten Inert Gas (TIG) welding, known for its exacting control and versatility, is favored for projects where the appearance and strength of the weld matter most. Precision Tig Welding techniques deliver several clear benefits:

• Exceptional Weld Quality: The process produces minimal spatter and allows for fine control over heat input, resulting in smooth, aesthetically pleasing joints.

• Versatility: Suitable for thin and thick materials, this method is ideal for everything from intricate automotive parts to robust industrial structures.

• Reduced Distortion: The focused heat of TIG welding minimizes warping, ensuring components fit together perfectly and maintain structural integrity.

• Superior Strength: Consistent penetration and fusion create welds that stand up to demanding applications, even under stress or corrosion.Essential Techniques for Stronger Fabrication

To unlock the full potential of Precision Tig Welding, practitioners should focus on mastering these core techniques:

1. Torch Angle and Travel Speed: Maintaining a 10–15 degree torch angle and steady travel speed ensures uniform bead formation and penetration.

2. Filler Material Selection: Matching the filler rod to the base metal type and thickness is critical for optimal weld strength.

3. Cleanliness: Always clean base metals thoroughly before welding to avoid contamination, which can weaken the joint.

4. Controlled Heat Input: Use a foot pedal or fingertip control to modulate amperage, preventing overheating and burn-through.Achieve Consistent Results

Establishing a repeatable process through careful setup and attention to detail is vital. High-quality tungsten electrodes, inert shielding gas (like argon), and precise parameter settings will consistently yield reliable welds suitable for prototype and production environments.

Micro Weld Inc. is a national leader in advanced metal joining solutions, specializing in TIG, MIG, and Medical Laser Welding for varied industries. Learn more about Micro Weld Inc. and take the next step toward achieving superior fabrication results with their expert services and innovative techniques.