Plating is a surface covering in which a metal is deposited on a conductive surface. Plating has been done for hundreds of years. It is also critical for modern technology. Plating is used to decorate objects, for corrosion inhibition, to reduce friction, to improve paint adhesion, to alter conductivity, to improve IR reflectivity, for radiation shielding, and for other purposes.

Zinc Creates a Barrier

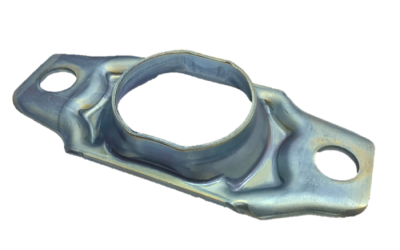

Zinc plating prevents oxidation of the protected metal by forming a barrier and by acting as a sacrificial anode if this barrier is damaged. Zinc oxide is a fine white dust that does not cause a breakdown of the substrate’s surface integrity as it is formed. Indeed the zinc oxide, if undisturbed, can act as a barrier to further oxidation, in a way similar to the protection afforded to aluminum and stainless steels. Most automotive parts are zinc plated.

Zinc Promotes Longevity

Zinc is the best ally of steel against one of its most natural enemies better known as rust. The protection afforded by zinc through the hot zinc-plating process may lengthen the average lifespan of steel products up to 30 years.

Zinc Provides Protection

Zinc plating provides a protective barrier between steel and the atmosphere; besides, in the case that cracks form in the zinc layer, zinc still protects steel catholically, and that is by forming a layer of insoluble zinc salts by ion movement towards the bare steel surface. The high quality zinc layer takes advantage from the unique properties of zinc and steel to protect your steel products.

Zinc Makes a Difference

Unprotected steel may last for 2 years before its functional and structural properties are compromised. Zinc-plated elements last instead up to 3 decades even when exposed to the most unfavorable conditions, with no maintenance required, thus allowing considerable reduction in maintenance costs and higher resistance.

Zinc Saves Resources

The zinc-plating process saves energy as it extends the lifespan of resources, as in the case of corroded steel that should be otherwise replaced from new iron ore. The zinc-plating process does indeed introduce small amounts of zinc waste into the environment. However, its high-tech processing allows for the minimization of noxious emissions.